GloBAS Engineers took part in the KISSsoft User webinar on Manufacturing Deviations and Flank Waviness.

With the help of KISSsoft, the user can now estimate the influence of manufacturing deviation on the resulting transmission error and excitation force.

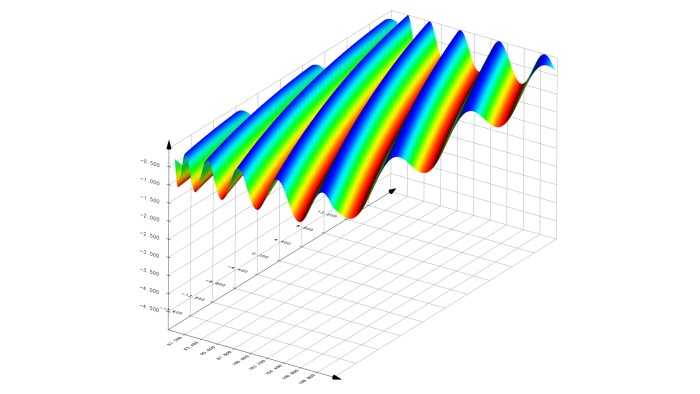

For the form deviations in the profile or flank line direction, a sinusoidal wave is applied to the theoretically ideal tooth flank. The waviness can be modified by amplitude, length and phase shift. By specifying an additional angular deviation, the total deviation is simulated.

These deviations can be executed in the profile direction, the width direction, or combined. The result is a change in the transmission error, excitation force and other significant influences on vibration excitation. The user can thus test how sensitively a theoretically specified tooth flank modification reacts to manufacturing deviations.

Noise emissions from gear units in electric vehicles are a major problem. In practice, the profile form deviation is greatly restricted. For this reason, it is reasonable to find a method that can be used to estimate the influence of manufacturing accuracy. The application of this method to some modern gear units was presented at the webinar from KISSsoft AG.:

– Application in the calculation

– Variation of the waviness

– Application to an industrial gearbox

– Application to an EV gearbox

The webinar is hosted by MSc. Eng. Tsikur (Senior Engineer – Global Sales) and held by Dr. Ulrich Kissling, founder and president of KISSsoft AG. Do not miss a chance to learn more about KISSsoft solutions in the one-to-one technical demonstration and book the time at contact@globasengineering.com

Dubai

Dubai