Utilizing CFD software has become an indispensable tool in reducing development costs by enabling users to quickly handle more realistic geometries and physics

The use of CFD helps maintain the quality and safety of many products that we use day in and day out, such as the car or even the house we live in. CFD software becomes indispensable for product development in the early stages of a project, to ensure that the best options are chosen early in the design process. The quality of the designed product can be improved at the conceptual design stage through basic investigation of the hydrogasodynamic and thermal processes that directly affect product performance.

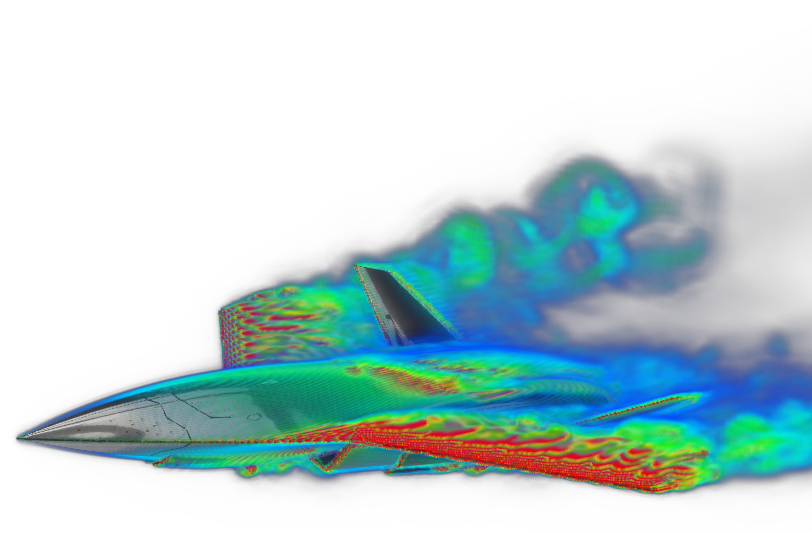

When visualizing gas or fluid flow movements, the picture can be quite complex. By incorporating Cradle CFD simulation software into the workflow, flow analysis is easier than ever. Users now have the ability to predict the performance of their products prior to in-situ testing. This, in turn, contributes to a more optimal design early in the product development cycle. In some cases, simulation can even completely replace the need for in-situ testing. Cradle CFD provides engineers with an understanding of fluid flow patterns and conditions and an easy-to-use tool that every designer can implement.

Typically, the goal of thermal calculations is to understand the behavior and performance of a structure when subjected to thermal loads. Depending on the simulation objectives, engineers can perform sequential or coupled calculations to study temperature changes and their effects on the behavior of the structure, both in terms of strength and potential for failure. The ability to create multiphysics models related to thermal radiation can be further enhanced by incorporating joule heat and electromagnetic effects to better represent the physics of behavior.

The systems we use allow us to model possible products and systems:

Let us know about your struggles and we will help you overcome them

YOUR ENGINEERING PARTNER IN THE MIDDLE EAST

© 2015 – 2022 GloBAS Distribution. All rights reserved.

© 2015 – 2022 GloBAS Distribution. All rights reserved.

Please, fill in the form below.

By leaving a request, you agree to the personal data processing policy