World's leading CFD technology

Smart Multiphysics Focused Computational Fluid Dynamics World's leading CFD technology available to boost smart manufacturing

Cradle CFD software solutions contain a range of applications designed to solve fluid and gas mechanics and heat transfer problems in the early stages of design, prior to full-scale experiments with physical prototypes. This software is indispensable in cases where setting up experiments is difficult or impossible, and there is a need to evaluate characteristics or perform measurements that are difficult or even impossible in full-scale tests.

Software Cradle has joined MSC Software Corporation and added computational fluid dynamics (CFD) software to the MSC family of software products.

Cradle CFD specialized applications include the scSTREAM, scFLOW hydrogasodynamic packages and the PICLS printed circuit board thermal simulation tool.

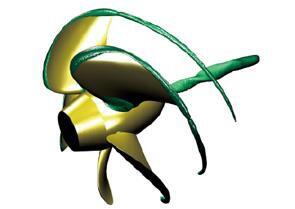

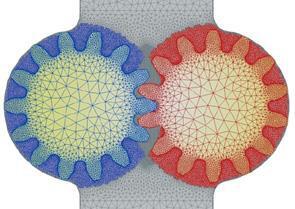

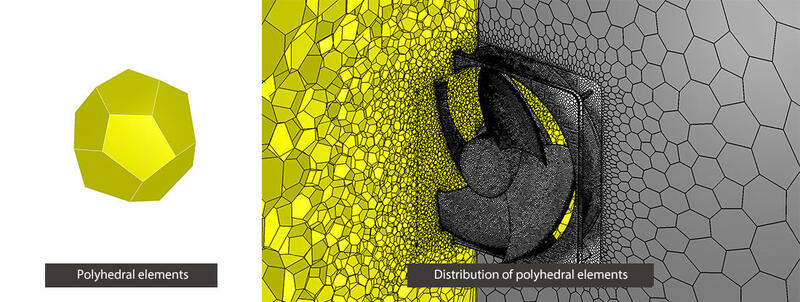

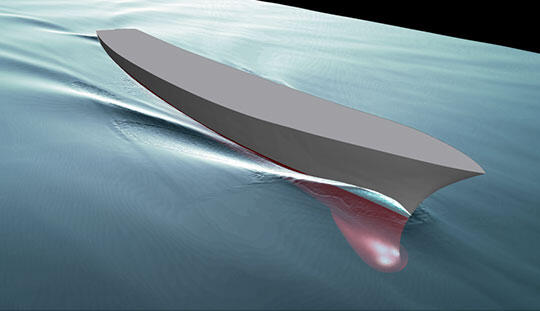

scFLOW is a general-purpose fluid dynamics package based on unstructured meshes, built using polyhedral and prismatic polyhedral elements.

The unstructured mesh allows to reproduce geometric features of models with high accuracy. Supported geometric formats include widely used Parasolid, STEP, IGES, ACIS, STL and highly specialized and proprietary ones.

A computational mesh can be built on imported geometry. Tools for modification, simplification or construction of additional elements of the computational model are available in the preprocessor. There is a technology for wrapping to create a streamlined surface or flow part of the computational model, for which the mesh will be built.

scSTREAM is a hydrogasdynamic package based on models with a structured finite-volume mesh, characterized by an extremely fast mesh generator and low-quality requirements for geometric models in the problem formulation.

This approach saves formulation time, disregarding the higher dimensional models as compared to the traditional grid.

Preprocessor scSTREAM provides a possibility to avoid time wasting on the preparation of the initial geometric model and to proceed immediately to the construction of the computational grid and setting task conditions.

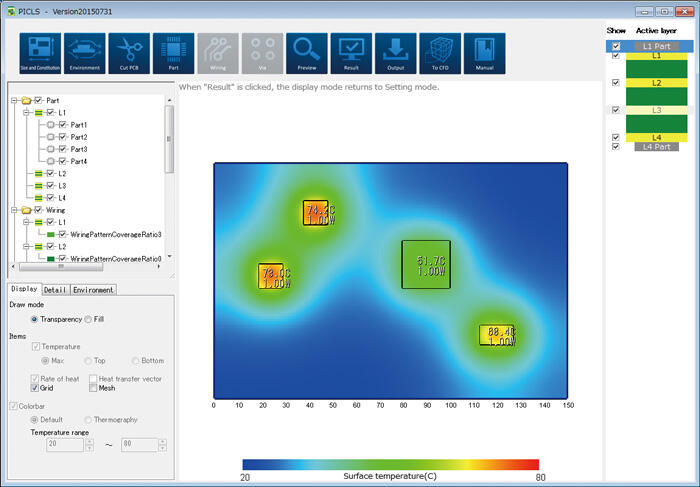

PICLS is a thermal modeling tool, which provides PCBs heat load analysis. Thanks to the simplicity and high speed of PICLS in 2D, the result of PCB analysis is available in real-time. A simple movement of components on a printed circuit board is instantly accompanied by a visualization of the recalculated thermal field.

Cradle CFD hydrogasodynamic process analysis can include additional options that allow creating models to analyze the following processes.

The scFLOW implements an extremely useful and efficient algorithm for automatically adapting the mesh to the problem. To use it, it is sufficient to formulate a problem and build a regular computational grid of average quality. The automatic algorithm then performs a series of calculations to adapt and rebuild the existing mesh, keeping track of the nature of the flow. This makes it possible to create, in semi-automatic mode, computational meshes of high quality and acceptable dimensionality, without the need for unreasonable multiple increases in the case of “manual” construction.

One of the strengths of scFLOW is its efficient mechanism for modeling moving elements as they interact with fluid media. Model elements can interact with each other, for example, a valve can overlap the flowing part of the model by contacting the walls of a pipeline, thereby completely or partially shutting off the flow. Another example: two movable rotating elements interact with each other and “push” the fluid – a gear pump. Such and many other problems are successfully solved using the intersecting grid methods, in which the grid moves together with the moving objects. In this case, the moving mesh is superimposed on a stationary one with automatic recalculation of results (Overset mesh).

For free bodies, buoyancy is implemented.

The interaction of Lagrangian and Eulerian meshes on arbitrary surfaces (Airbirary Lagrangian-Eulerian – ALE) and the Mixing plane method, which implements cyclic boundary conditions to reduce the dimensionality of the problem, are provided.

You can request a trial version of the full package for testing. The trial is followed with a technical demonstration aimed on software abilities and focused on your design and manufacturing purposes.

In case of interest please contact us or fill the form below.

YOUR ENGINEERING PARTNER IN THE MIDDLE EAST

© 2015 – 2022 GloBAS Distribution. All rights reserved.

© 2015 – 2022 GloBAS Distribution. All rights reserved.

Please, fill in the form below.

By leaving a request, you agree to the personal data processing policy