In the modern world, when designing complex structures and they certainly can be called modern gearboxes and auxiliary transmission elements, it is impossible to use only one type of calculation.

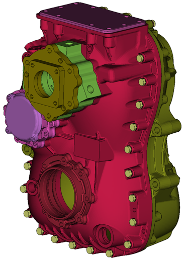

Consider, using the example of a simple element from a truck transmission, the process of calculations from internal elements to the design as a whole.

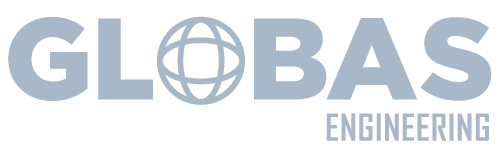

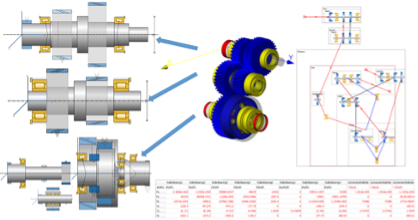

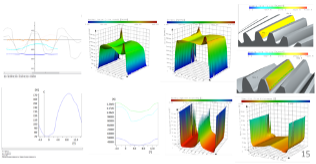

At the first stages of design, when we have only general requirements for the future product (dimensions and parameters of the transmitted power), but do not yet have its external appearance, we assemble the internal structure in the KISSsoft® program to debug shafts, gears, determine the operating modes of bearings, identify design bottlenecks, etc.

At this stage, we receive all the necessary information about how the filling of our product will work under different loading conditions.

The next step is to add external elements to our stuffing, and if at the initial design stage, we can take into account the external case as an element with given stiffness parameters, then in the future we need to switch to a real design.

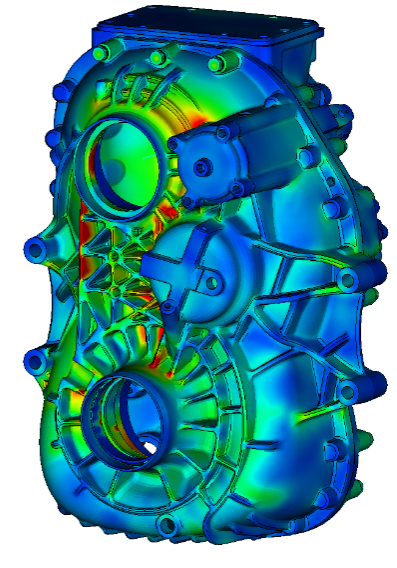

The ability to correctly transfer data on the operation of bearings, forces and moments in their cages gives us the opportunity to correctly apply loads to the body of the future product. The gearbox body itself is not just rigidly fixed in the model, but the boundary conditions that correspond to the actual mode of its operation must be applied to its supports. With this approach, we can not only check how the operation of internal elements will affect the body, but also, if necessary, predict possible places of body failure under extreme conditions.

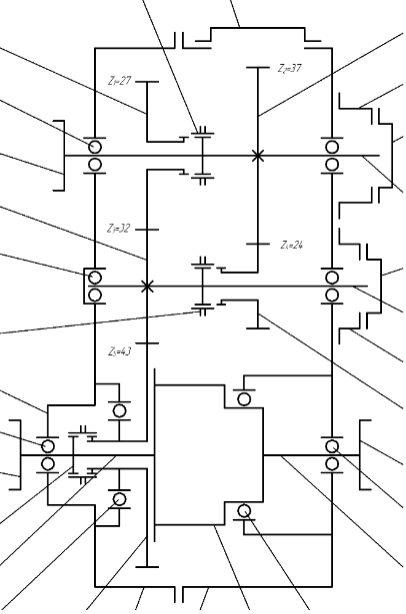

In addition to the calculations of statics and dynamics, we must necessarily add two more types of computational studies. The study of the thermal modes of the product operation will identify areas with loss of landing tolerances and possible misalignments of the shafts. The NVH study will give us a picture of the noise performance of our product, which is very important as the noise requirements are getting tougher all the time.

Do not forget that the study of the noise level should be carried out taking into account the presence or absence of lubrication inside the product, and here the use of the ParticleWorks software module, together with RecurDyn, will come to our aid.

Thus, with a competent design approach, we can avoid most design errors at the design stage.

Our company is ready to provide all the necessary services to help both create digital models of products and provide support in design. Join our free-of-charge online introductory session on Monday, March 27th at 18:00 Dubai time

We will be happy to share the knowledge, discuss your tasks and challenges, and help your company to achieve the ambitious targets as fast and effectively as possible. Do not hesitate to contact us for support and free consultation.

Or feel free to schedule a personal meeting or online technical discussion.

Dubai

Dubai